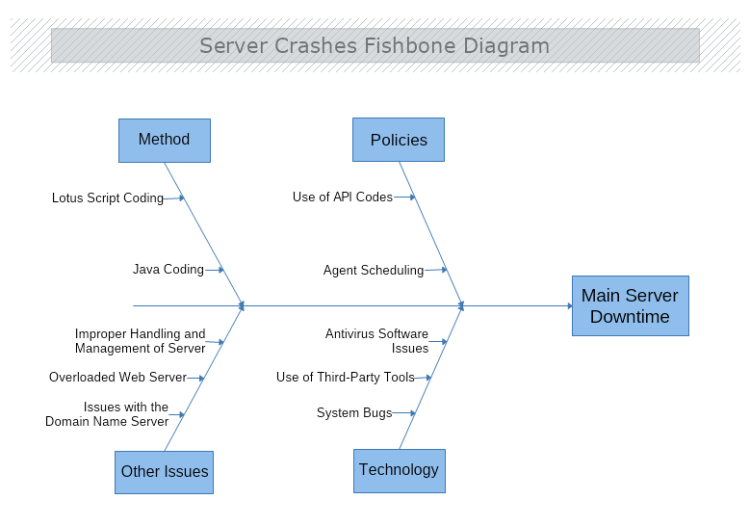

You can also search articles, case studies, and publications for fishbone diagram resources. The resulting diagram illustrates the main causes and subcauses leading to an effect (symptom). Start using the fishbone diagram template and analyze process dispersion with this simple, visual tool. "Iron tools" can be considered a "Methods" problem when taking samples or a "Manpower" problem with maintenance personnel. "Calibration" shows up under "Methods" as a factor in the analytical procedure, and also under "Measurement" as a cause of lab error. Note that some ideas appear in two different places. Layers of branches show thorough thinking about the causes of the problem.įor example, under the heading "Machines," the idea "materials of construction" shows four kinds of equipment and then several specific machine numbers. The team used the six generic headings to prompt ideas. This fishbone diagram was drawn by a manufacturing team to try to understand the source of periodic iron contamination. When the group runs out of ideas, focus attention to places on the chart where ideas are few.Layers of branches indicate causal relationships.

Continue to ask "Why?" and generate deeper levels of causes. Write sub-causes branching off the causes. Again ask "Why does this happen?" about each cause.Causes can be written in several places if they relate to several categories. Ask "Why does this happen?" As each idea is given, the facilitator writes it as a branch from the appropriate category. Brainstorm all the possible causes of the problem.Write the categories of causes as branches from the main arrow.If this is difficult use generic headings:

Draw a box around it and draw a horizontal arrow running to it. Write it at the center right of the flipchart or whiteboard.

0 kommentar(er)

0 kommentar(er)